Industrial automation is an industrial production process that includes a set of machines through which raw materials are transformed into final products through work and processing. Mankind is always making a significant effort to develop sophisticated and modern techniques to help people with various productive tasks.

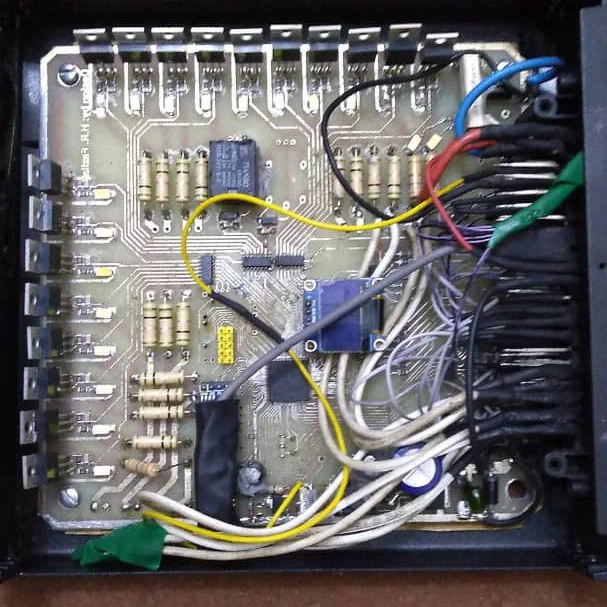

In the process of industrial automation, the term “machine” can be anything such as a motor, drill, conveyor belt, solenoid valve, gearbox, etc., under the name of electromechanical devices or chemical machines such as furnaces, dryers, chemical combustion systems. and so on. Today, industrial automation has a major impact on the production process of products and it is almost difficult to produce without this automation system. Tools like PLC and microcomputer boards are among these automation tools.

There are several factors that lead to the implementation of the automation system in industrial production:

- Need for high quality goods

- High expectations on product reliability

Electronic Automation

It is a process that works with machines and other industrial equipment with the help of logical digital programming and reducing human intervention in decision-making and manual command process with the help of mechanized equipment.

For example: without electronic automation, the operator must first adjust the amount of fuel in the oven by controlling a valve to bring the temperature to the desired value. After reaching the required temperature, it should be maintained by continuously adjusting the valve, i.e. increase or decrease the fuel according to the temperature for the next 30 minutes.

Now, with industrial electronic automation, entire processes are handled without operator assistance. First, there is a temperature sensor near the oven that reports the temperature to the microcomputer in the PLC. There is a solenoid valve that is also controlled by the computer to connect the fuel to the stove. Based on the temperature received from the heat sensor, the computer opens the solenoid valve to initially have more fuel. After reaching the desired temperature, the solenoid valve turns off.

Therefore, the microcomputer continuously monitors the temperature and controls the fuel delivery amount by adjusting the solenoid valve. . Therefore, the fatigue of the human operator is no longer involved, and a task is performed accurately and continuously with the PLC.

The Purpose of industrial Automation

Basically, the implementation of automation in a manufacturing process focuses on replacing a human worker with a machine with an independent processor. Initially, these autonomous machines had to be coordinated by a human supervisor for a smooth production process. But with technological advances in analog and digital control systems, microprocessors and PLCs (programmable logic controllers) and various sensors, it has become very easy to synchronize multiple independent machines and processes and achieve true industrial automation. With the rise of the industrial economy, the industrial automation business strategies have also changed over time. The basic goals for implementing automation are:

- Increasing the production of goods and products in a shorter period of time

- Reducing production costs, especially costs related to human labor

- Improve product quality

- Effective use of raw materials and less production waste

- Reducing energy consumption with greater accuracy in measurement

- Increasing business profits due to the optimal use of energy and materials